- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China Polyester Needle Felt Filter Bags Manufacturer, Supplier, Factory

As a professional Polyester Needle Felt Filter Bags manufacturer and supplier in China, we have our own factory and can provide quotations. You can buy discount and low price Polyester Needle Felt Filter Bags.

Hot Products

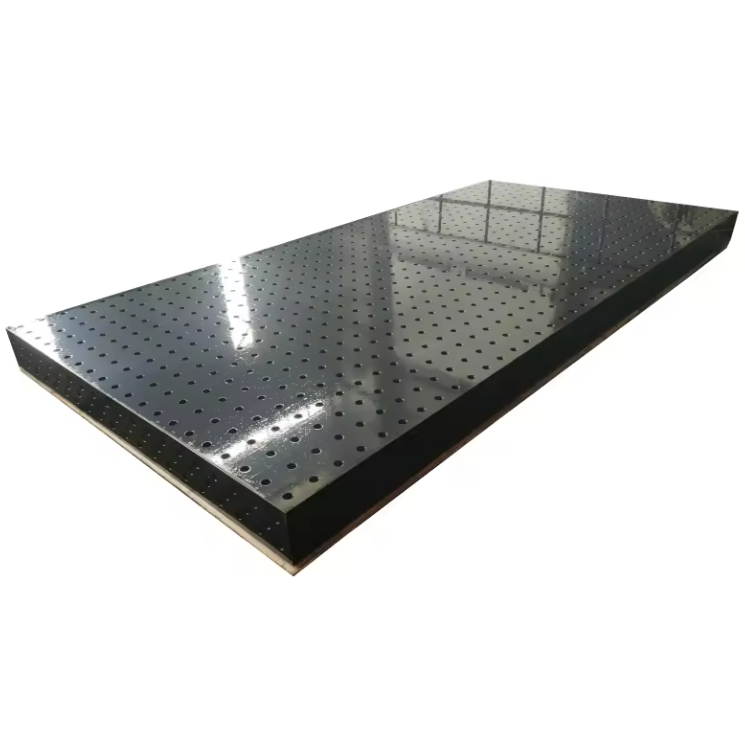

Good Soldering Station

The core components of SRD Good Soldering Station include PLC, engine, bearing, gearbox, motor, pressure vessel, gear, pump, etc. At present, our company's two-dimensional welding station only produces D28 series. The same hole spacing is also 100*100, and the working surface is also processed with 100*100 spacing grid lines. The good welding station is suitable for a variety of welding jobs when combined with the D28 series tooling fixtures. The surface of the work surface can be treated with anti-rust treatment, such as nitriding process.Explosion proof Downdraft worktable

The SRD Explosion proof Downdraft worktable, sourced from a reputable manufacturer and supplier in China, embodies the pinnacle of quality and innovation in surface finishing solutions. Flumex High Temperature Resistant Felt Bag

The Botou Xintian SRD durable Flumex High Temperature Resistant Felt Bag, a cutting-edge dust removal equipment, is a product uniquely crafted by our company for cement plants. Leveraging our proprietary technology, it effectively collects dust produced during cement manufacturing. As a result, we have emerged as the designated supplier of dust removal equipment to numerous prominent cement plants, earning ourselves a reputation as one of the most reliable manufacturers of cement dust collector equipment in China.Polyester Dust Collector Filter Bag

The Botou Xintian Polyester Dust Collector Filter Bag, meticulously manufactured in China by our esteemed company, exemplifies our dedication to quality and reliability. As a leading supplier of filtration solutions, we offer competitive pricing without compromising on the exceptional quality and performance of our products, ensuring unmatched value for our customers.Dust Collector Dust Discharge Valve

Botou Xintian SRD cement plant Dust Collector Dust Discharge Valve for cement plants developed by our company. It uses proprietary technology to collect dust generated by cement plant production. Our company has become the designated supplier of dust removal equipment for many major cement plants and is one of the most trusted manufacturers of cement dust collector equipment in China by customers.Welding U-shaped Square Box

Botou Xintian SRD is a professional welding table manufacturer. We also produce related accessories. There are mainly two series: D28 and D16, including welding U-shaped square boxes for welding table. After nitriding, the durability can be improved. We have Years of production experience. It is the most trusted welding table manufacturer by customers.