- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China Welding Table Bolts Manufacturer, Supplier, Factory

As a professional Welding Table Bolts manufacturer and supplier in China, we have our own factory and can provide quotations. You can buy discount and low price Welding Table Bolts.

Hot Products

Nitrided steel welding table

Nitrided steel welding table is a welding workbench made of nitriding steel material. 1. Durable and sturdy: The nitride steel welding table has high strength and hardness, allowing it to withstand heavy welding equipment and workpieces without deformation or damage. 2. High temperature resistance: High temperatures are generated during the welding process, and nitride steel welding tables can withstand these high temperatures well without affecting their performance due to heat. 3. Corrosion resistance: Nitrided steel welded tables have a certain degree of corrosion resistance and can be used in harsh working environments without rusting easily. 4. Good stability: Nitrogen steel welding tables require good stability to ensure the accuracy and safety of welding operations. Nitrided steel welding tables are usually designed reasonably, structurally stable, and can meet this requirement.Electrostatic Precipitators

Botou Xintian SRD is a professional electrostatic precipitator manufacturer and supplier with rich experience in the production and installation of electrostatic precipitators. We produce electrostatic precipitators and related accessories through our own factory, all of which are made in China and are reasonably priced. If you are interested in our products, look forward to our long-term cooperation.Industrial Filter Bag

The Botou Xintian SRD Industrial Filter Bag, meticulously manufactured in China by our esteemed company, embodies our commitment to quality and innovation. As a leading supplier, we offer competitive pricing without compromising on the superior quality and performance of our products, ensuring unmatched value for our customers.Air-conditioning DT Pipeline Shock-absorbing Bracket

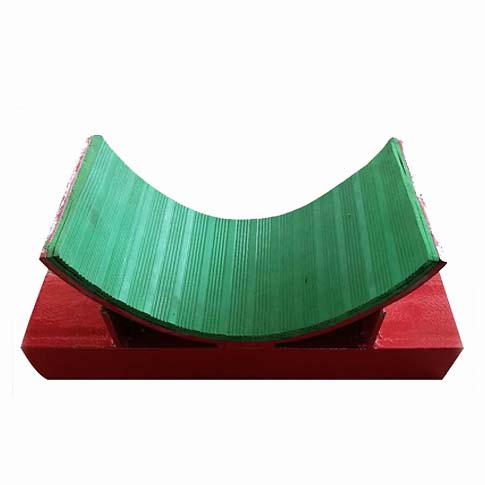

The Botou Xintian SRD Air-conditioning DT Pipeline Shock-absorbing Bracket, exquisitely crafted in China by our esteemed manufacturer, embodies our unwavering commitment to quality and reliability. As a leading supplier, we provide competitive pricing without sacrificing the superior quality and performance of our products, thereby ensuring unparalleled value for our esteemed customers.Dust Filter Bag Cage

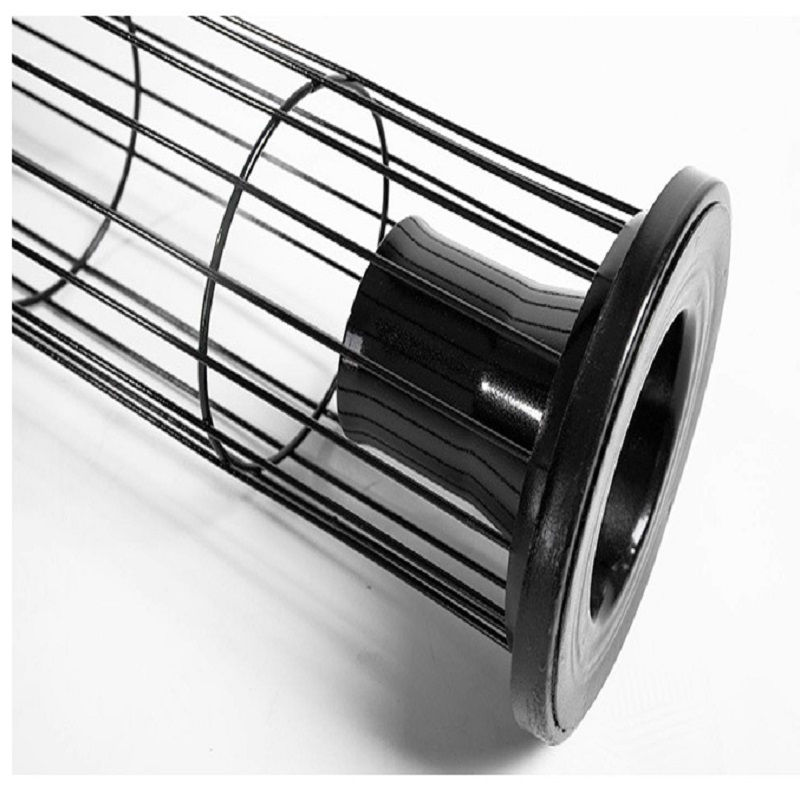

The Botou Xintian SRD cement plant dust collector, a highly efficient Dust Filter Bag Cage, is a cutting-edge product uniquely developed by our company. This innovative technology effectively collects dust emitted during cement plant production. As a result, our company has been chosen as the designated supplier of dust removal equipment for numerous prominent cement plants, firmly establishing ourselves as one of the most reliable manufacturers of cement dust collector equipment in China.Cloth Bag Dust Collector

The Botou Xintian SRD Cloth Bag Dust Collector, meticulously manufactured in China by our esteemed company, offers superior quality and reliability at competitive prices, ensuring efficient dust collection and optimal performance for various industrial applications.